Choose your viewer type

Set your role once and we will tailor the guidance across SIP University.

A clean sign-off

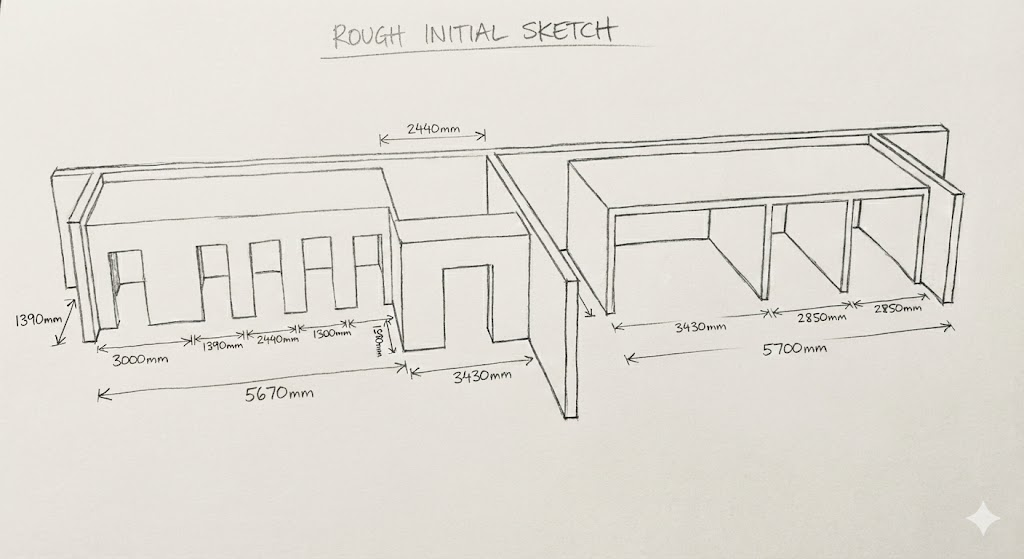

Quotes stall when structural intent and site access are vague. When drawings and logistics are clear, the sign-off pack becomes a labelled, install-ready delivery. UltraSIPS treats signed drawings as the contract for what arrives on site.

Ordering is where scope turns into price and lead time, so clarity here avoids delays later.

Step 1: Define the scope

A SIP order starts with clarity. What are you building, what level of finish, and what parts are included? The scope defines the quote and the drawing package.

Step 2: Provide the core inputs

Your supplier will need:

- Architectural plans and elevations

- Structural intent (load-bearing walls, roof type)

- Site constraints (access, delivery, crane)

- Configurator output from configurator-dev.ultrasips.com for sizes and panel counts

Step 3: Quote and estimate

The estimate is a translation of drawings into panel quantities, splines, and fixings. This is the moment to confirm panel thickness, core type, and any special detailing.

Step 4: Review layout drawings

Layout drawings show panel numbers, dimensions, openings, and connection details. Review carefully. This is where errors are cheapest to fix.

Step 5: Sign off and manufacture

Once drawings are signed off, production begins. Panels are cut, labeled, and packaged for delivery. Changes after sign-off can cause delays and extra cost.

Step 6: Delivery and staging

Plan delivery for crane access and storage. Panels should be stacked in install order and protected from weather until used.

Order process checklist

- Confirm scope, inclusions, and exclusions.

- Provide complete drawings and structural intent.

- Review and sign off layout drawings.

- Lock delivery date, access, and staging.

- Plan install sequence before the kit arrives.