Choose your viewer type

Set your role once and we will tailor the guidance across SIP University.

Design that saves days

Design works best when the layout follows a clear grid and load paths are mapped early. Off-grid bays and awkward openings multiply cuts and grow the pack. Snap to a 1200mm rhythm and the kit tightens up. UltraSIPS can sanity-check the grid early so you avoid rework.

Design decisions lock the kit, so early clarity protects cost, lead time, and site workflow.

Start with the grid

Think in panels, not studs. SIPs work best when you align wall lengths and roof spans to standard panel widths. That means fewer cuts, cleaner joints, and faster installation.

Load design charts: pick the right table

Load design charts keep you honest. In the UK, wind exposure, snow load, and roof pitch all change what a panel can do. Use the charts for strength and deflection, and confirm which combinations are acceptable for walls, floors, and roofs.

Comparison

Load design charts compared

Different charts answer different questions. Use the right one at the right moment.

Wall axial load charts

Gravity loads

- Check how much roof and floor load a wall panel can carry

- Identify when posts or splines are required

- Confirm bearing at openings

Roof span charts

Pitch, snow, wind

- Span varies with pitch and loading

- Confirm deflection limits for ceilings and finishes

- Use UK wind and snow values

Floor span charts

Live load driven

- Use residential and storage load cases

- Confirm vibration and deflection limits

- Check bearing length requirements

Deflection checks

Serviceability

- Strength is not enough if deflection is high

- Choose thickness that keeps finishes intact

- Check both short and long term movement

Spline connections: choose the right joint

Splines connect panels and carry load across joints. The right spline balances structure, thermal performance, and speed of install.

Comparison

Spline connection types

Match the spline to the load and the build speed you need.

OSB or plywood spline

Standard wall joints

- Cost effective and widely used

- Good for typical wall loads

- Moderate thermal bridge

OSB block spline

Higher bearing

- Adds more bearing area

- Useful at openings and higher loads

- Slightly more labour to fit

Lumber or EWP spline

High capacity

- Handles higher point loads

- Straightforward site fastening

- Thermal bridge is larger

I-joist spline

Tall walls

- Strong and stable for tall panels

- Good alignment for long runs

- Requires precise routing

Cam lock connection

Fast assembly

- Factory precision speeds install

- Ideal for repeatable modules

- Needs CNC and exact panel prep

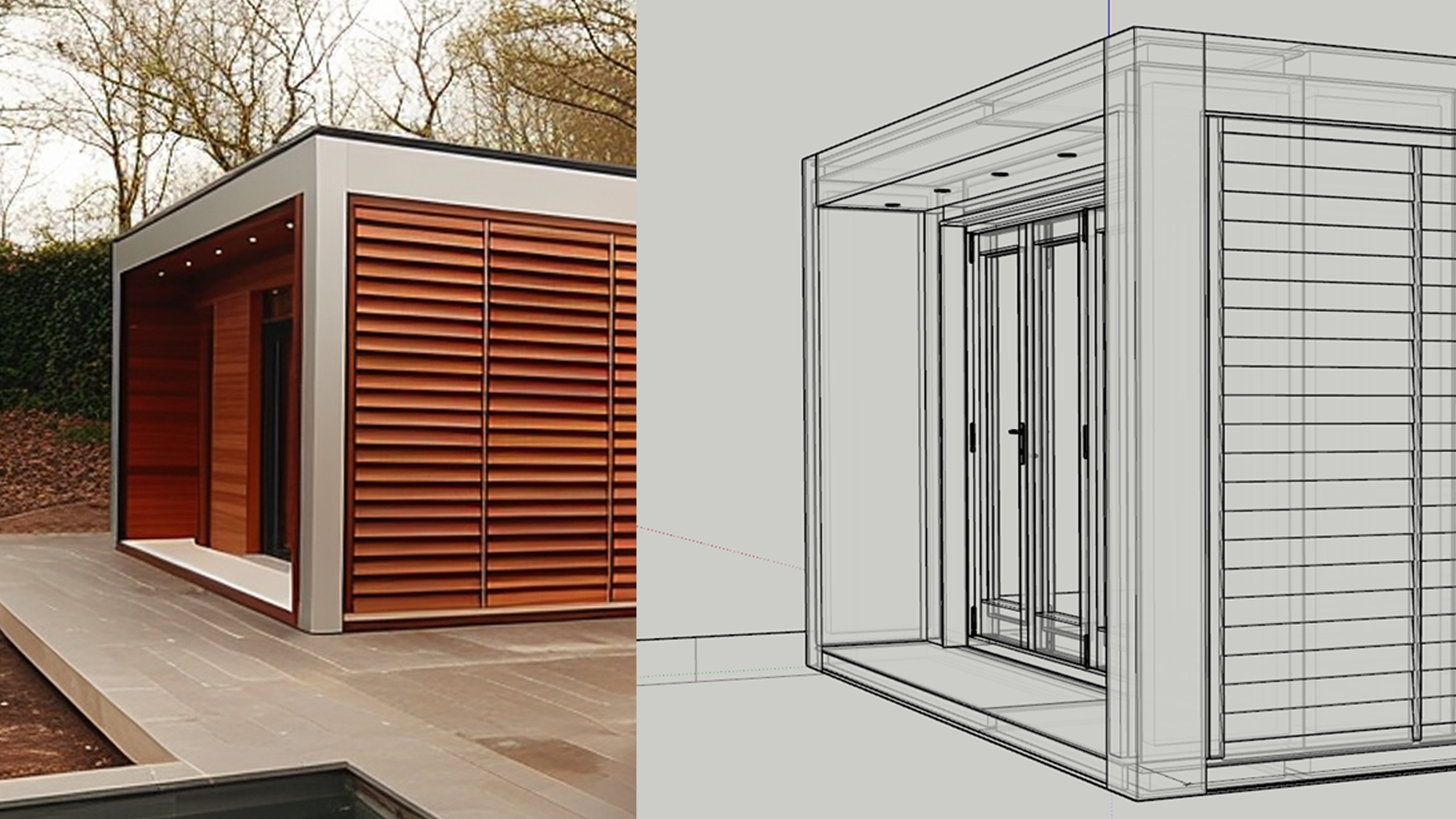

Panel-friendly architecture

SIPs love simple geometry. The more you align the form to panel sizes, the less waste and on-site modification you face.

Comparison

Panel-friendly forms compared

Simple forms cut weeks. Complex geometry needs more engineering and more time.

Simple rectangles and clean offsets

- Fastest to panelize and install

- Minimal waste and fewer splines

- Best for cost and programme

Gable roofs and single pitches

- Panels land on predictable bearing lines

- Simple ridge and eaves details

- Less need for secondary structure

Dormers and valleys

- Extra joints and custom details

- More engineering and more cutting

- Plan early to avoid delays

Cantilevers and complex offsets

- Higher engineering input

- More splines or steel support

- Transport and install complexity

Floor SIPs vs joists

Floor SIPs can speed the shell, but they are not always the best answer. Decide based on span, loads, and service routes.

Comparison

Floor systems compared

Choose the system that best fits the span and service plan.

SIP floor panels

- Fast enclosure with insulation built in

- Good for clear spans and airtightness

- Plan services early

I-joist or timber floors

- Easy routing for services

- Lower panel cost in some builds

- More time on site for insulation

Hybrid floor approach

- SIP floor where speed matters

- Joists where services dominate

- Balanced cost and programme

Architect or designer?

Different roles own different decisions. You need a clean handoff so the SIP design does not drift from the architectural intent.

Comparison

Who owns which decision

Clarity up front prevents late-stage redraws.

Architect

- Overall form, planning, and layout intent

- Window and door positioning

- Client-facing decisions

SIP designer

- Panel grid, splines, and joints

- Shop drawings and panel schedules

- Assembly logic and install sequence

Structural engineer

- Loads, point loads, and lateral forces

- Beam sizing and key connections

- Compliance with UK standards

Builder or site lead

- Practical access and lifting plan

- Sequencing and storage plan

- Feedback for buildable details

Design considerations that move the kit

The details below change the cut list and the cost. Bring them forward, not after the panels are drawn.

Comparison

Design considerations that change the kit

Small layout choices can make big changes to price and lead time.

Span and loading

- Longer spans mean thicker panels

- Higher loads need stronger splines

- Roof pitch and snow matter

Openings and headers

- Openings off-grid create extra trimming

- Headers can require posts or beams

- Plan glazing sizes early

Services and chases

- Large services need routing space

- Plan penetrations before manufacture

- Avoid cutting key load paths

Transport and access

- Panel size affects delivery and crane plan

- Tight sites may require smaller panels

- Confirm staging space

SIP CAD outputs

The right drawings keep everyone aligned: architect, factory, and site.

Comparison

Design outputs compared

Each output answers a different question.

Architectural CAD model

- Defines overall form and layout

- Sets window and door intent

- Not a manufacturing model

SIP shop drawings

- Panel sizes, splines, labels

- Exact cut paths for CNC

- Factory and QC reference

Installation layouts

- Panel numbering and sequence

- Crane picks and staging

- Site build checklist

Engineering schedules

- Loads, spans, and fixings

- Beam and post callouts

- Compliance notes

SIP designer decisions

SIP designers make a series of linked calls that drive cost, performance, and install speed.

Comparison

Key SIP designer decisions

These choices determine how the kit behaves on site.

Panel thickness

- Driven by span and U-value

- Thicker panels add cost and weight

- Balance performance and handling

Spline type

- Structural demand sets the spline

- Thermal bridges need attention

- Keep splines consistent where possible

Joint placement

- Align joints to load paths

- Avoid joints at critical openings

- Reduce site cutting

Opening strategy

- Stay on the grid where possible

- Confirm lintels and posts

- Coordinate glazing early

Connection details

- Wall-to-floor alignment

- Corners and internal walls

- Roof bearing details

Manufacturing constraints

- CNC limits and transport sizes

- Tolerances and labeling

- Lead time implications

Wall-to-floor connection

The wall-to-floor detail carries load and sets airtightness. Choose the detail that fits the build.

Comparison

Wall-to-floor connection options

Pick the detail that matches loads and install sequence.

Bottom bearing on sole plate

- Simple and common detail

- Good for slab or floor deck

- Easy to line and seal

Panelized floor with spline

- Fast enclosure with fewer trades

- Good airtightness continuity

- Requires careful service planning

Ledger or hanger

- Useful when aligning with existing structures

- Allows floor to hang off SIP walls

- Check deflection at hangers

Insulated rim SIP

Rim details are common leakage points. Choose a detail that keeps insulation continuous.

Comparison

Rim strategies compared

Keep thermal continuity at the floor edge.

Standard rim board

- Simple and familiar

- Needs extra insulation

- Higher thermal bridge risk

Insulated rim SIP

- Continuous insulation at perimeter

- Improves airtightness

- Requires accurate detailing

Thermal break rim

- Good for retrofit conditions

- Reduces cold bridging

- Detailing must be precise

Wall corner connections

Corners are load paths and airtightness zones. Pick the detail that fits the structure.

Comparison

Corner connection options

Corners must carry load and resist racking.

Two-panel spline corner

- Standard SIP corner detail

- Simple to fabricate and seal

- Works for most wall heights

Post corner

- Handles higher loads

- Good when openings are close to corners

- Adds a thermal bridge

Insulated corner panel

- Reduces thermal bridging

- More complex to fabricate

- Needs careful sequencing

Interior wall connection

Interior partitions can be structural or non-structural. The detail changes the kit.

Comparison

Interior wall connection options

Match the detail to the load.

Non-loadbearing spline

- Lightweight partition

- Simpler sealing

- Keep it away from major load paths

Loadbearing post or spline

- Transfers vertical loads

- Common under ridge or beam lines

- Check bearing and fixing detail

Service partition

- Creates a space for services

- Protects the panel envelope

- Can improve airtightness

Hanging floor detail

Hanging floors save height but need clear load transfer.

Comparison

Hanging floor approaches

Choose the detail that keeps deflection under control.

Ledger and hangers

- Compact floor detail

- Common in extensions

- Check fixing schedules

Dropped beam support

- Higher capacity for longer spans

- Clearer load path

- Adds depth below

Cantilever with reinforcement

- Useful for overhangs

- Requires engineered detail

- Watch deflection and uplift

Bevel cut top of wall

Pitched roofs need the right bearing detail to keep panels square and sealed.

Comparison

Top-of-wall detailing

Match the detail to the roof pitch.

Bevel cut wall top

- Direct bearing for roof panels

- Clean and efficient detail

- Needs precise cutting

Flat top with sleeper

- Adds flexibility for roof layout

- More tolerance on site

- Extra timber and fixings

Truss seat with bearer

- Good for hybrid roof systems

- Keeps load transfer clear

- Requires coordination with truss design

Point loads

Point loads are where panels can be overstressed. Spread the load and define the path.

Comparison

Point load strategies

Spread the load and protect the panel faces.

Bearing post

- Direct load transfer

- Best for heavy beams

- Needs accurate alignment

Load spreader plate

- Distributes load across skins

- Useful for smaller point loads

- Requires detailing in drawings

Steel beam pocket

- Saves headroom

- Needs engineered reinforcement

- Avoids crushing the core

Load transfer: two strategies

Load transfer can go through continuous wall lines or be handed off to beams. Decide early.

Comparison

Load transfer strategies compared

Choose the strategy that keeps the structure simple.

Continuous load path

- Loads drop straight to the foundation

- Simpler detailing

- Often the most cost effective

Transfer to beams

- Useful for open plans

- More engineering and coordination

- Watch deflection and bearing points

Lateral forces on walls (wind)

Wind and racking loads dictate splines, hold-downs, and nail schedules.

Comparison

Lateral load strategies

Keep racking resistance continuous through the structure.

Shear wall nailing

- Standard SIP racking resistance

- Requires correct nailing schedules

- Check corners and openings

Hold-downs and straps

- Resist uplift and overturning

- Critical in high wind exposure

- Coordinate with foundation bolts

Diaphragm tie

- Roof and floor panels act together

- Needs continuity at joints

- Check fixings and spline type

Tall walls

Tall walls need extra attention to stability and deflection.

Comparison

Tall wall options

Choose the build method that keeps walls straight.

Single tall panel

- Fewer joints

- Fast install

- Requires careful handling

Stacked panels

- Easier lifting and handling

- More joints to seal

- Good when access is tight

Platform break

- Uses intermediate floor as brace

- Simplifies logistics

- More detail coordination

Doghouse dormers

Dormers are the definition of custom. Decide whether they are panelized or framed.

Comparison

Dormer approaches

Keep dormer geometry simple whenever possible.

Panelized dormer

- Fast install with fewer trades

- Good for repeatable forms

- Requires clear detailing

Stick-built dormer

- Flexible on site

- Slower and more labour

- Often used for one-off shapes

Hybrid approach

- Panelize main roof

- Frame the complex dormer bits

- Balanced programme

Ridge or purlin beam material choices

Beam choice affects weight, cost, and lead time.

Comparison

Beam materials compared

The beam dictates how the roof panels bear.

Glulam

- Strong and visually warm

- Common in UK roof designs

- Lead time depends on supplier

LVL

- Consistent and strong

- Often cost effective

- Requires protection and lining

Steel

- Highest capacity for tight spans

- Slim profile saves headroom

- Needs careful thermal breaks

Ridge details

Ridge details affect air sealing and structure.

Comparison

Ridge detail options

Pick the detail that matches structural intent.

Structural ridge beam

- Clear load path

- Simple roof panel bearing

- Requires beam coordination

Ridge spline

- Panel-to-panel connection

- Works on lighter roofs

- Check uplift and deflection

Cap plate ridge

- Simplifies finishing

- Useful for low pitch roofs

- Needs robust sealing

Roof details

Roof panels can be vented or unvented depending on climate and build-up.

Comparison

Roof build-up strategies

Choose the build-up that matches UK moisture and energy goals.

Cold roof (vented)

- Ventilation path above insulation

- Traditional roofing approach

- Requires clean vent paths

Warm roof (unvented)

- Continuous insulation at roof line

- Simpler airtightness detail

- Requires moisture control

Hybrid roof

- Service void plus insulated panels

- Good for MVHR routing

- More layers to coordinate

Internal valley beams

Valleys need clear drainage and solid structure.

Comparison

Valley structure options

Prevent leaks by keeping structure and flashing clear.

Valley beam

- Simple load path

- Good for clear interior lines

- Needs clean flashing detail

Valley truss

- Lightweight roof framing

- More movement to consider

- Often slower to install

Panelized valley

- Fast install when geometry is simple

- Requires careful detailing

- Limited by panel sizes

Roof penetrations

Penetrations are leak risks. The best solution is to design them into the panel pack.

Comparison

Penetration strategies

Factory planning is safer than cutting on site.

Factory cut and reinforced

- Cleanest and most precise

- Keeps airtightness detail intact

- Preferred for MVHR and flues

Site cut with framing

- Flexible for late changes

- Higher risk of air leaks

- Needs careful reinforcement

Curb assembly

- Useful for large rooflights

- Allows flashing control

- Adds height and complexity

Extreme engineering

Some designs are beyond a standard kit. Know when to involve structural engineering early.

Comparison

When to call for engineering

Complex geometry and loads need specialist input.

Standard SIP kit

- Simple spans and rooflines

- Straightforward openings

- Fastest approval path

Long spans or cantilevers

- Requires bespoke beams

- Higher deflection risk

- Engineering input essential

Multi-storey or heavy loads

- Load paths become complex

- More hold-downs and posts

- Coordination with structural engineer

Standard detail pack (reference)

Need the full UltraSIPS standard detail drawings? View the reference pack here: UltraSIPS Standard Details.

Design checklist

- Align walls to standard panel widths.

- Mark openings early and keep them on-grid.

- Choose splines based on load, not habit.

- Validate spans and deflection with manufacturer tables.

- Confirm roof details, penetrations, and beam choices before manufacturing.