What this detail covers

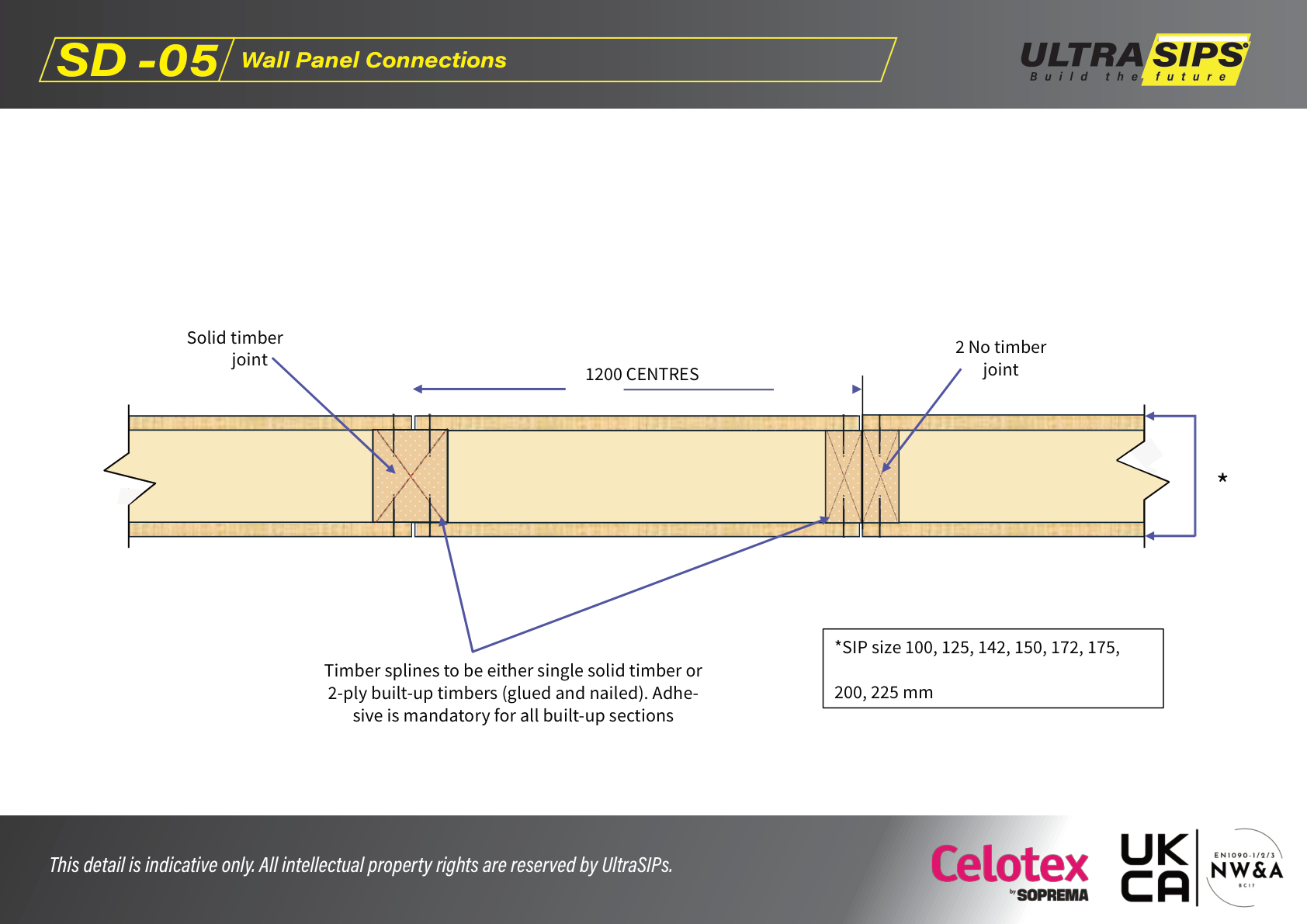

- Typical wall panel connection layout and spacing (often 1200 centres).

- The difference between joints with solid timber and “no timber” joints (where specified).

How to use it on a real job

- Confirm the panel thickness and joint type in the kit drawings/spec.

- Keep panel joints aligned to the intended centres to match openings and structural intent.

- Use the corresponding rebate/spline prep details before closing joints.

Checks

- Joint type matches the drawings for that panel run.

- Panel centres and openings line up with the layout drawings.

Common mistakes

- Mixing joint types within a run (creates fit-up and fixing issues).

- Drifting off the grid early, then “correcting” later with site cuts.

Indicative only: always follow the engineer’s fixing schedule and the project drawings.